Tramp oil separator

WHEN OIL ACTS LIKE SAND IN OPERATION: MKR TRAMP OIL SEPARATORS FOR TRAMP OIL SEPARATION WITH AND WITHOUT UV STERILISATION.

KEEPS COOLANT, MACHINES AND EMPLOYEES FIT.

Tramp oils reduce the effect of emulsions and solutions. Reduced service life and spreading microorganisms are the consequences. Removal of these oils is the first step to hygienic and cost-effective production.

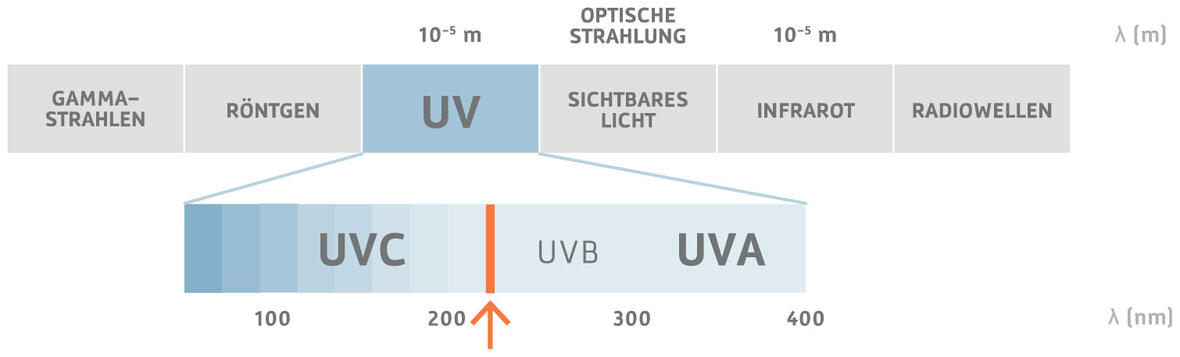

With the TrennMaster, MKR goes even further. The installed special UV flat bed reactors significantly improve the appearance and odour of process media. The likewise mobile unit can also remove tramp oil and eliminate microorganisms. It operates with the bypass method, i.e. while production is running.

The oil is separated according to the coalescence principle. This means floating tramp oils are removed from the surface by floats and are carefully added to an intermediate tank. A special coalescence package removes dispersed oil droplets from the emulsion, which are refreshed and available once more for cooling.

TRAMP OIL SEPARATOR AREAS OF APPLICATION

- Metalworking fluid care

- Extraction of floating tramp oils

- Cleaning and care of individually filled units

- (in the external bypass cycle)

- -Cleaning of washing and pretreatment baths

PERFORMANCE CHARACTERISTICS OF TRAMP OIL SEPARATORS:

- Reduction of germs and odours

- Extension of the visually good condition of the emulsion

- Bypass cleaning without machine standstill

- Reduction of emulsion consumption (concentrate)

- Reduction of disposal costs

- Optimisation of cleanliness and air quality at the workplace

- Short payback period

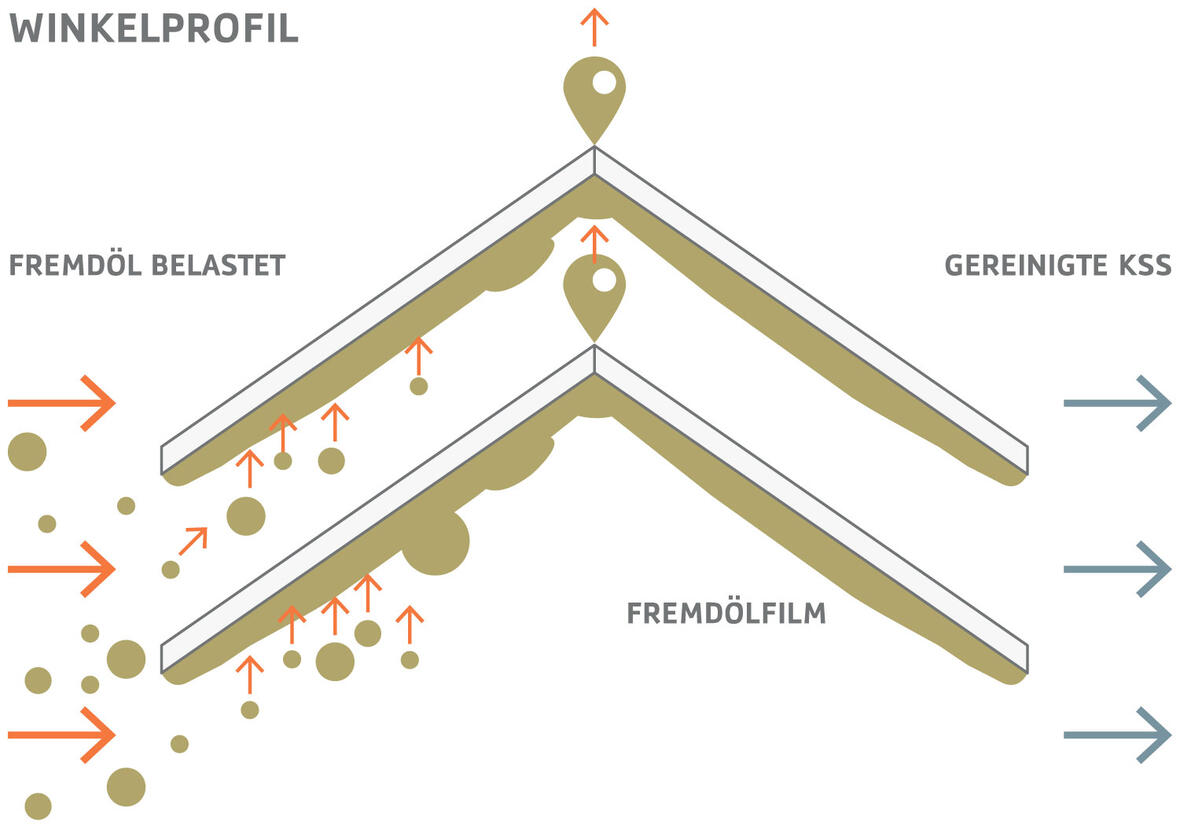

PROCESS

In the MKR tramp oil separators the oil is separated according to the coalescence principle. Floating tramp oils are removed from the surface by floats and are carefully added to an intermediate tank. A special coalescence package removes dispersed oil droplets from the emulsion, which are refreshed and available once more for cooling.

HOW COALESCERS WORK

The smallest oil droplets deposit on the slats and “coalesce” to form larger droplets. The oil rises through special drillholes. In this way, highly dispersed droplets can also be removed effectively by MKR tramp oil separators.