Use washing water longer – save costs and resources with

Reliable treatment of cleaning media

in industrial parts cleaning

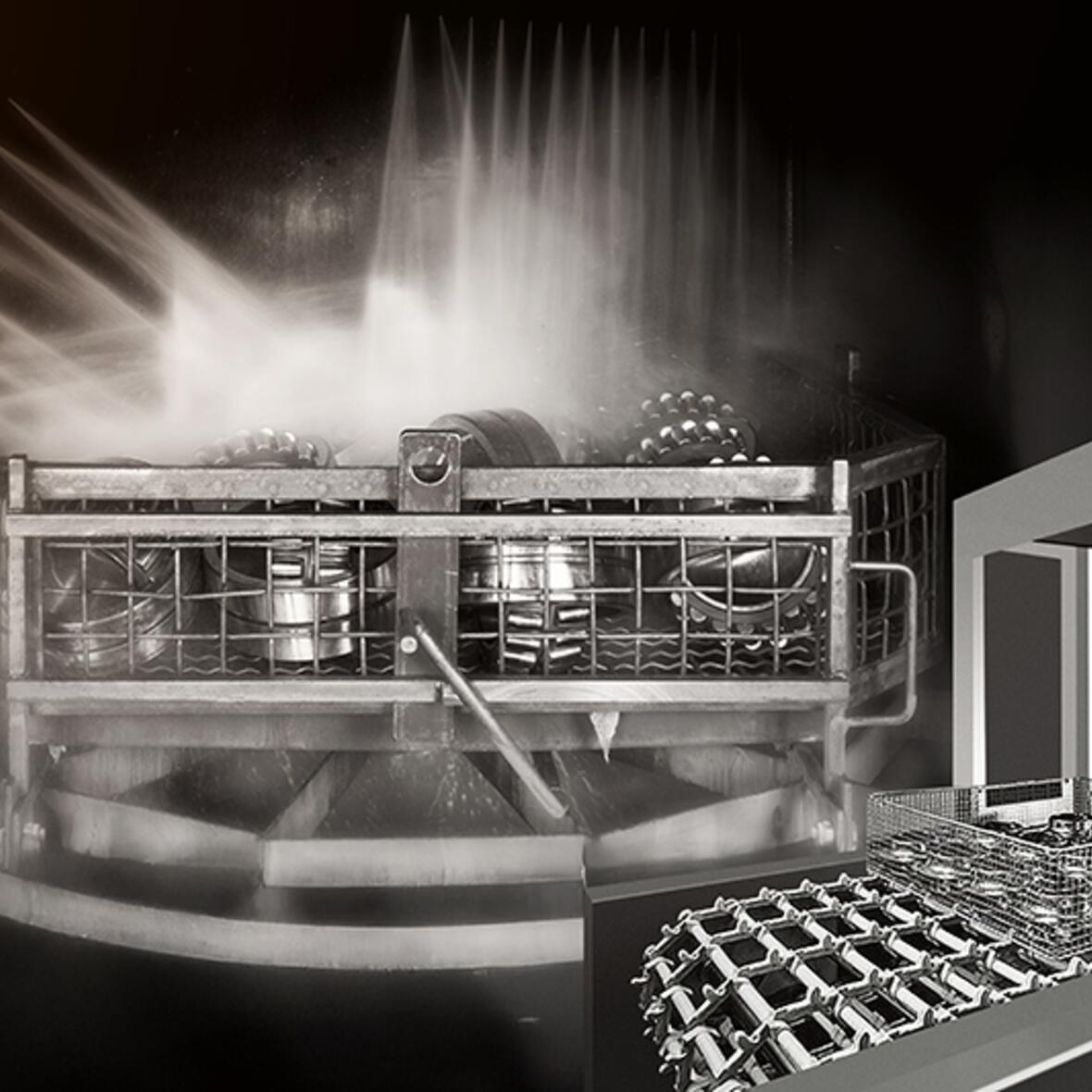

In industrial parts cleaning—whether before assembly, after machining, or between process steps—the cleanliness of the components plays a decisive role in product quality. However, the aqueous cleaning media used quickly become contaminated with oil, grease, and dirt particles. Without treatment, baths must be changed frequently – with correspondingly high costs for disposal, re-dosing, and downtime.

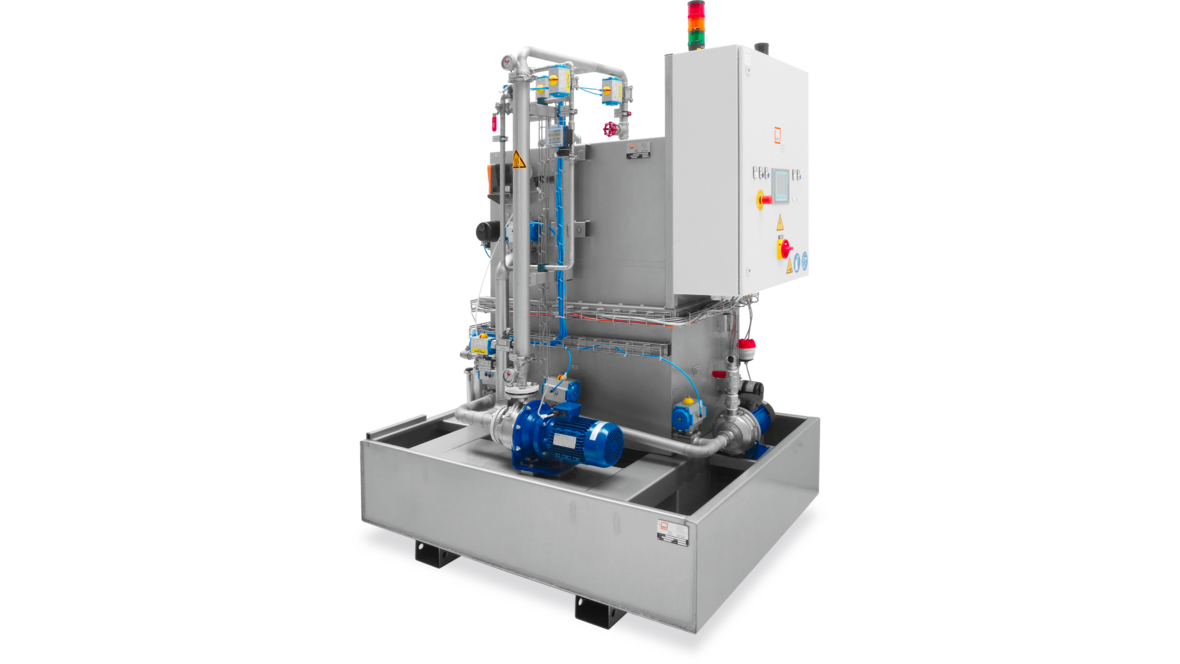

With our MKR ultrafiltration systems of the UC series , the service life of the washing water can be significantly extended. Contaminants and emulsions are reliably separated, while the cleaning medium is returned to the process in high quality.

Sustainability meets cost-effectiveness

Every unnecessary bath change not only costs chemicals and water, but also valuable production time. With an MKR ultrafiltration solution, you can significantly reduce these losses:

- Longer service life of cleaning baths

- Reduced chemical consumption

- Lower disposal volumes

- Continuously stable cleaning quality

With our ROI calculation tool , we work with you to determine the profitability of the investment—individually, transparently, and practically. This allows you to see at a glance how quickly the system will pay for itself in your business.

MKR ultrafiltration systems operate fully automatically and continuously in bypass mode – ideal for long-term industrial use in parts cleaning.

Your advantages at a glance

Extended bath life by a factor of several times

Reduction of disposal and operating costs

More stable cleaning processes and component quality

Lower chemical and fresh water consumption

Fast ROI – calculable with our tool

Compact, robust technology "Made in Germany"

Areas of application

Typical areas of application

- Aqueous cleaning systems in metalworking

- Pre-cleaning and intermediate cleaning in assembly

- Fine cleaning prior to coating or painting processes

- Wash water treatment for combined oil/particle contamination

Optimize processes efficiently and sustainably

Would you like to increase the efficiency of your parts cleaning while saving costs?

With our MKR ultrafiltration systems and the accompanying ROI tool, we will find the right solution for your process—sustainable, economical, and reliable.

Frequently asked questions

Our Evaporator systems

Maximum energy efficiency through mechanical vapor compression: Our fully automatic evaporators consume only 35 Wh/liter. Recover hygienized distillate of the highest quality for direct reuse in your production.

Our ultrafiltration systems

Our UC series uses purely mechanical ultrafiltration to separate particles, oils, and emulsions—completely without chemicals. Extend the service life of your cleaning baths many times over and ensure the consistently high quality of your process fluids.