Efficient wastewater treatment in paint pretreatment

Consistent water quality – for perfect painting results

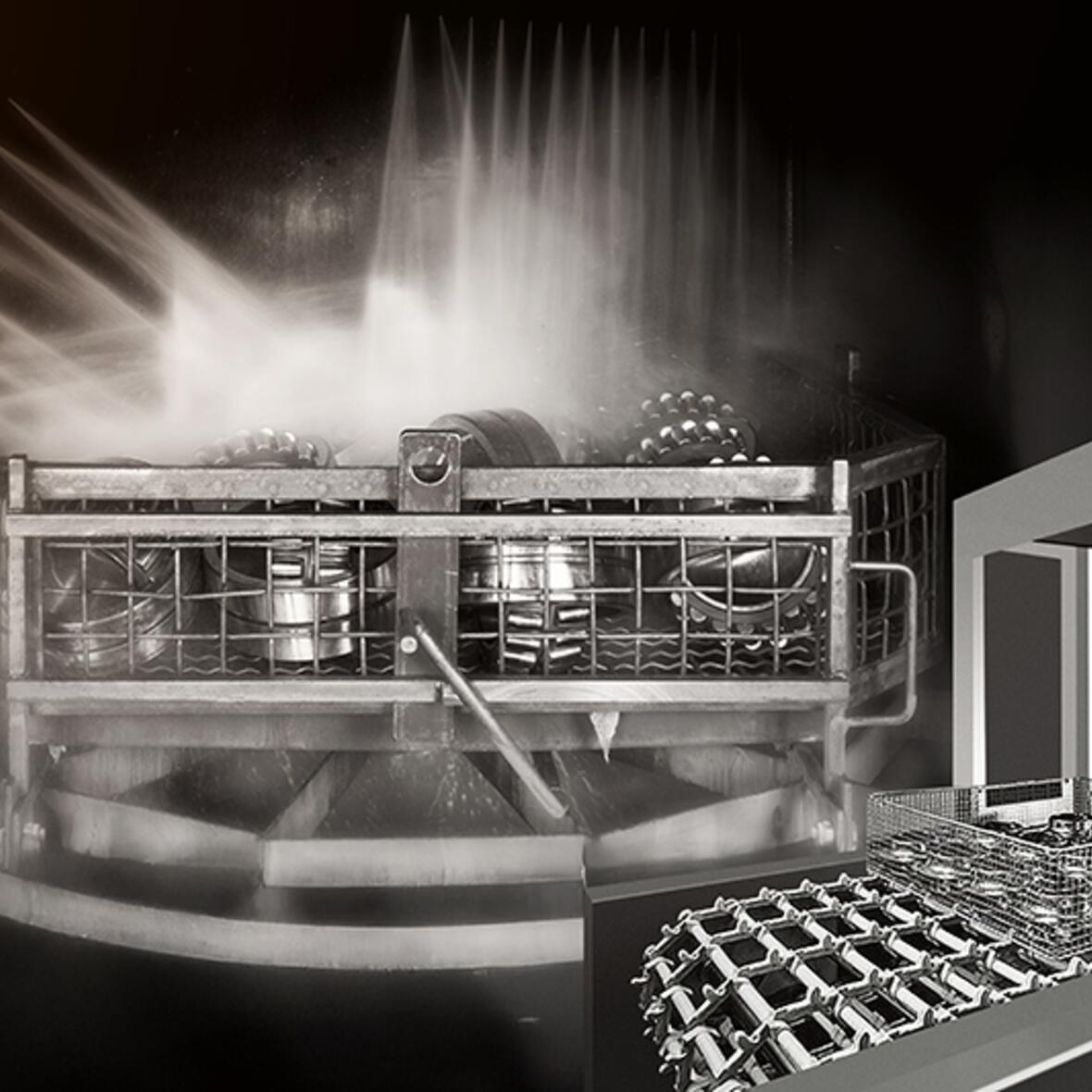

Whether body parts, housing components, or support profiles—, painted surfaces are standard in almost all industrial products. But before the paint can be applied, thorough paint pretreatment is necessary. This process produces large quantities of rinse and process water that is contaminated with cleaning chemicals, phosphates, metal ions, or degreasing agents.

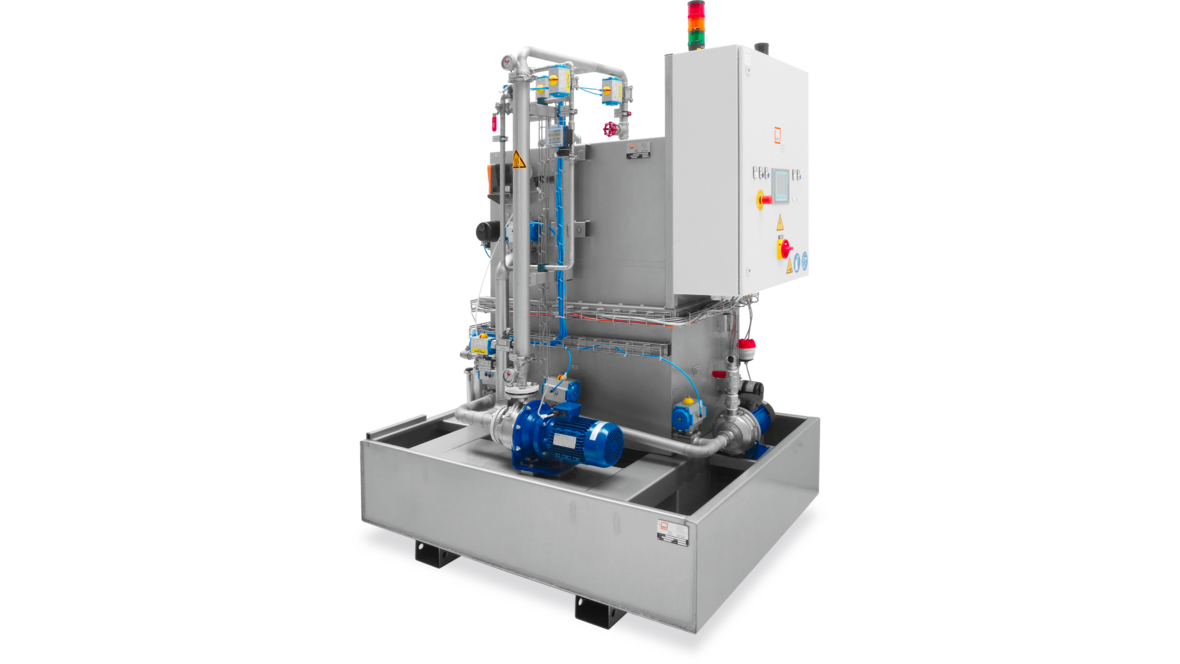

With MKR's atmospheric evaporators , this water can be treated safely, economically, and in compliance with legal requirements—and, if necessary, in such a way that the treated water can be returned to the process.

Sustainable recycling instead of discharge

MKR offers customized system solutions for the safe treatment of typical wastewater from pretreatment – including:

- pH adjustment • Filtration (bag filters, belt filters)

- Pre-separation of oils, particles, sludge

- Atmospheric evaporator

- Optional discharge monitoring (pH, temperature, volume)

- Reverse osmosis system / ion exchanger for VE recirculation flush

Individually customized – for all pretreatment processes

Whether iron phosphating , zinc phosphating, degreasing , or modern nanoceramic systems : we design the systems precisely according to your requirements—taking into account the chemicals used, the desired recovery rate, and the available space.

Your advantages at a glance

Stable process water quality for consistently good painting results

Reuse of water purified by the

is possible

Reduction of wastewater volume by up to 95%

Less waste disposal, lower chemical use, lower costs

Customized system concepts – compact and modularly expandable

Robust technology for continuous industrial operation

Areas of application

Typical wastewater types in paint pretreatment

- Degreasing baths (alkaline, neutral, acidic)

- Rinsing water from iron and zinc phosphating

- Rinsing water from pickling, nanoceramics or chrome-free conversion

- Media containing blasting agents

- Residues from wetting agents and corrosion inhibitors

Optimize processes efficiently and sustainably

Do you want to ensure quality while saving costs and resources?

With MKR, you can rely on proven evaporator technology , combined with practical planning and expert advice.

Frequently asked questions

Our Evaporator systems

Maximum energy efficiency through mechanical vapor compression: Our fully automatic evaporators consume only 35 Wh/liter. Recover hygienized distillate of the highest quality for direct reuse in your production.

Our ultrafiltration systems

Our UC series uses purely mechanical ultrafiltration to separate particles, oils, and emulsions—completely without chemicals. Extend the service life of your cleaning baths many times over and ensure the consistently high quality of your process fluids.