VAPORISER TECHNOLOGY IN THE MOBILITY INDUSTRY

In the mobility industry, which includes both the automotive and aerospace sectors, the challenge of wastewater management is an important aspect. Specific wastewater is produced in the various production processes, whether in die casting or electroplating. This wastewater in the mobility industry can contain a wide range of substances, including emulsions.

Evaporator technology in the mobility industry offers an advanced solution to this challenge. With this technology, wastewater can be effectively treated and processed so that it can be reused in the production process. Evaporation technology in the mobility industry therefore not only enables efficient wastewater treatment, but also contributes to a closed cycle and supports the industry's sustainability efforts.

We offer customised solutions for evaporator technology in the mobility industry that are tailored to the specific requirements and needs of the individual sectors. Our evaporator technology is an effective and environmentally friendly way of dealing with waste water and saving resources at the same time. We are thus setting new standards for sustainable water management in the mobility industry and contributing to a greener future.

COHLINE FOCUSES ON SUSTAINABILITY WITH VAPORISER TECHNOLOGY IN THE MOBILITY INDUSTRY

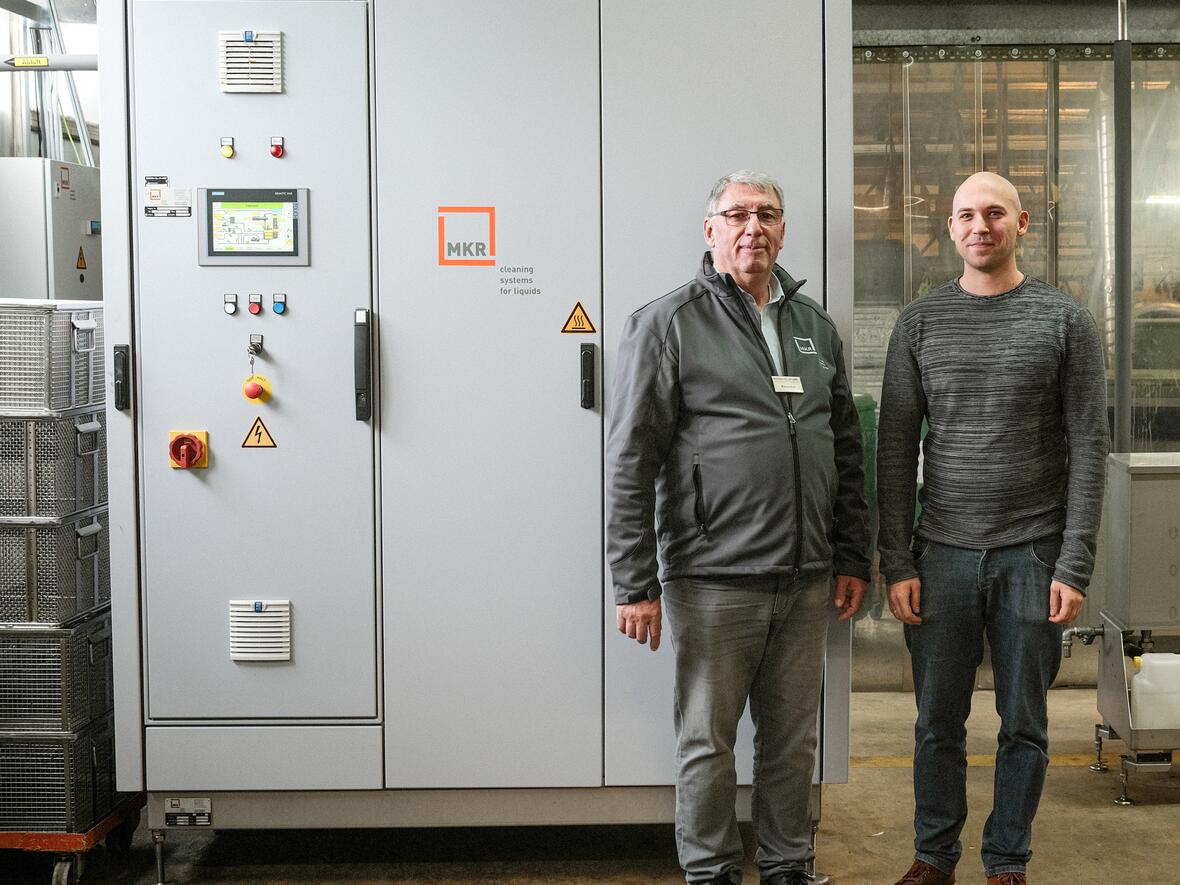

COHLINE, a leading manufacturer in the automotive industry, has successfully integrated vaporiser technology in the mobility industry by opting for the ET 50 vaporiser system from MKR-Metzger. This decision underlines COHLINE's commitment to efficient and environmentally friendly solutions in the mobility industry. By introducing evaporator technology, COHLINE Dillenburg was able to treat two different process water streams internally, resulting in significant savings and a reduction in CO2 emissions. Evaporator technology therefore not only enables cost savings in the mobility industry, but also effective reuse of the treated water.

The successful commissioning of the ET 50 evaporator system in autumn 2022 was a result of the partnership between COHLINE and MKR-Metzger. This partnership demonstrates the efficiency of evaporator technology in the mobility industry. The ET 50 vaporiser can be used for various liquids such as water, acids and alkalis and represents the high quality of vaporiser technology. MKR-Metzger, known for its innovative solutions in the field of water treatment, develops customised evaporator technologies that meet the special requirements of the mobility industry. The experienced team of engineers and technicians at MKR-Metzger specialises in the development and implementation of evaporator technologies in the mobility industry to achieve optimal results.

Evaporator technology in the mobility industry is a key element for environmental protection and cost reduction. Companies like COHLINE that invest in vaporiser technology show how innovative solutions can help improve the environmental footprint and increase profitability. Vaporiser technology in the mobility industry is therefore not only a technical solution, but also an important step towards a more sustainable future.

Image: Successful partnership at eye level: Sales Manager Gisbert Kieser (MKR-Metzger GmbH) together with Jens Wallulli (COHLINE GmbH) in front of the ET 50 evaporator system from MKR-Metzger.