About us

MKR METZGER - CLEAN, SUSTAINABLE AND EFFECTIVE

Your waste water is covered by an oil layer, is silty and unusable? MKR helps you to make your washing water reusable! With MKR you maintain your metalworking fluids, your washing media and pretreatment media effectively and not only save material but also disposal costs.

MKR offers you effective solutions for metalworking fluid cleaning, the cleaning of oils and washing media with the help of filtration, treatment and disposal. Let us advise you!

Location

MKR Metzger GmbH in Monheim has a total of 55 employees in its consulting, development, design, sales, service and administration departments. Support for customers abroad is provided by long-standing local partners. Know-how and problems solutions from MKR are mainly used in metalworking production firms as well as in other industries; these include, for example, suppliers of the automotive industry in Europe, North America and Asia. Other customer groups include companies specialised in coating as well the disposal of hazardous waste. MKR Metzger GmbH is wholly-owned by the Metzger family.

Production

From competent advice through to intelligent solution

We offer you a full service from A to Z. Our production benefits from our long-standing experience and know-how in welding, bending, assembly and in general in metalworking. Our products carry the "Made in Germany” quality characteristic and are produced in our location in Monheim with maximum precision and high production depth. MKR Metzger has 55 employees in its consulting, laboratory, 3D design, electrical design and programming, project planning, after-sales service and administration departments. We work together efficiently and reliably to produce solutions especially tailored to the wishes of our customers!

We offer you a full service from A to Z. Our production benefits from our long-standing experience and know-how in welding, bending, assembly and in general in metalworking. Our products carry the "Made in Germany” quality characteristic and are produced in our location in Monheim with maximum precision and high production depth. MKR Metzger has 55 employees in its consulting, laboratory, 3D design, electrical design and programming, project planning, after-sales service and administration departments. We work together efficiently and reliably to produce solutions especially tailored to the wishes of our customers!

Why MKR?

Effective

Increase productivity, save costs

MKR machines enable optimum productivity with low energy consumption. You even save valuable work time and spare your employees to boot. The quick and simple handling of the machines also contributes to the effectiveness.

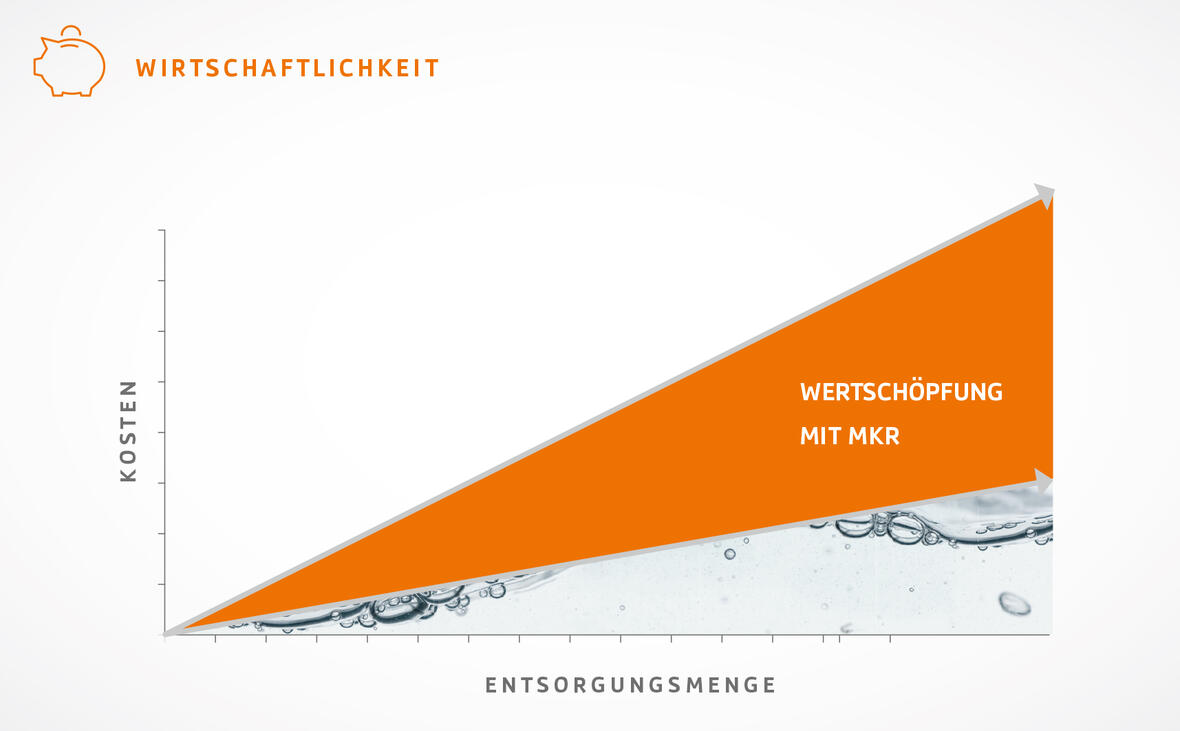

Economy

Lower disposal costs mean greater return

With our MKR systems you save costs, effort, time and energy Our machines enable significant savings in overall costs as well as a marked increase in productivity for your company. Contamination of process media through foreign oils, ultra-fine particles and micro-organisms restrict the operating time of industrial production systems, in some cases significantly. MKR recycling systems effectively eliminate such disruptive factors by means of filtration, separating and treatment systems. This ensures that cooling lubricant, cutting oils, washing liquids and other process media can continue to be used for significantly longer. This means: Fewer (disposal) costs and more return. Investments in the cleaning and reconditioning of process media pays off in many ways. This allows more than just cost savings for energy, materials, labour costs and disposal. The integrated recycling of process media also ensures consistently high quality and more efficiency in production. Our company offers modular problem solutions for ecological and economical optimisation of production circuits with liquid requirements. The consistent re-use of process media with the expertise and systems from MKR Metzger will generate the maximum economical and ecological advantages for your company. This means real sustainability – in the interests of future-proofing your company and also in the context of protecting resources and the environment.

With our MKR systems you save costs, effort, time and energy Our machines enable significant savings in overall costs as well as a marked increase in productivity for your company. Contamination of process media through foreign oils, ultra-fine particles and micro-organisms restrict the operating time of industrial production systems, in some cases significantly. MKR recycling systems effectively eliminate such disruptive factors by means of filtration, separating and treatment systems. This ensures that cooling lubricant, cutting oils, washing liquids and other process media can continue to be used for significantly longer. This means: Fewer (disposal) costs and more return. Investments in the cleaning and reconditioning of process media pays off in many ways. This allows more than just cost savings for energy, materials, labour costs and disposal. The integrated recycling of process media also ensures consistently high quality and more efficiency in production. Our company offers modular problem solutions for ecological and economical optimisation of production circuits with liquid requirements. The consistent re-use of process media with the expertise and systems from MKR Metzger will generate the maximum economical and ecological advantages for your company. This means real sustainability – in the interests of future-proofing your company and also in the context of protecting resources and the environment.