Process water treatment in the aviation industry

how-to-treat-process-water-in-the-aviation-industry In the aviation industry, environmental protection and resource efficiency requirements are constantly increasing—including in maintenance. MRO (maintenance, repair, and overhaul) companies, which service aircraft and components throughout their entire life cycle, are required to treat process water responsibly and operate sustainably.

Parts cleaning, electroplating processes, crack testing, and mechanical processing , all generate different types of wastewater: oily, heavy metal-containing, salty, or chemically contaminated. These must be treated reliably and in compliance with the law – or disposed of at great expense.

With our atmospheric evaporators, we offer an efficient, internal solution for treating this process water – individually customizable and energy optimized. In many cases, the purified distillate can be reused as needed. This not only reduces your operating costs, but also your environmental footprint – and saves up to 98% of your previous disposal costs .

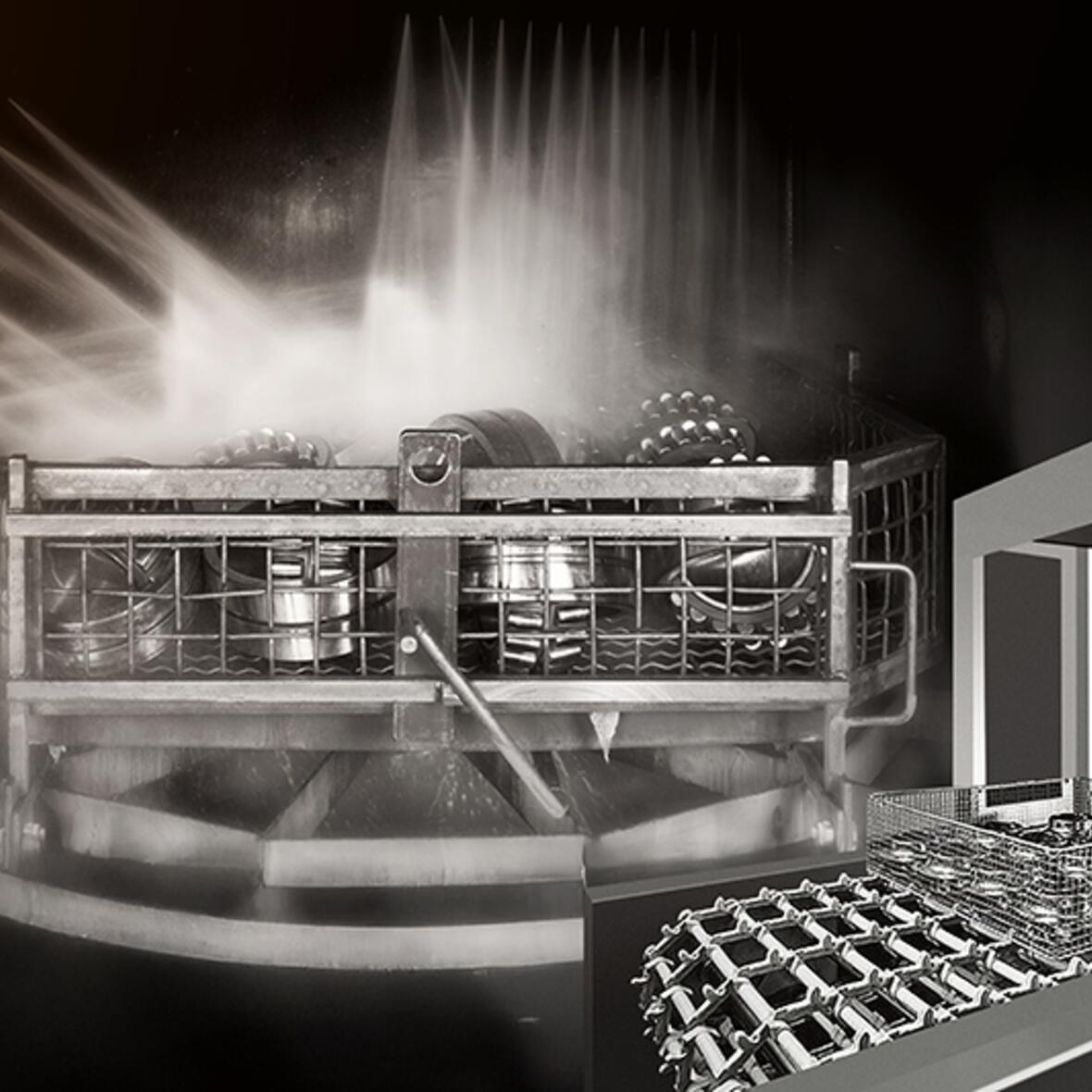

Sewage-free thanks to crack testing

In particular, crack testing — e.g., using dye penetration methods — in the (German Institute for Standardization) produces cleaning water containing special testing agents that must not be discharged directly into the sewage system. Our technology makes your testing processes virtually wastewater-free , safe, and economical.

Your advantages at a glance:

Efficient treatment of a wide variety of process water

Reuse of water purified by the

Massive reduction in disposal costs

High operational reliability – low personnel costs

Fast return on investment

Sustainable contribution to your environmental management

Areas of application

Typical wastewater in the aviation industry:

- Wastewater from the Crack testing

- Washing water from parts cleaning

- Used Cooling lubricants

- Oil-containing wastewater from washing and rinsing processes

- Heavy metal or salt-containing water from electroplating or hardening

- and many other special media

Optimize processes efficiently and sustainably

Would you like to make your maintenance or wastewater treatment processes more efficient and sustainable?

We will show you how our solutions can help you not only meet legal requirements, but also reduce costs and achieve environmental goals.

Frequently asked questions

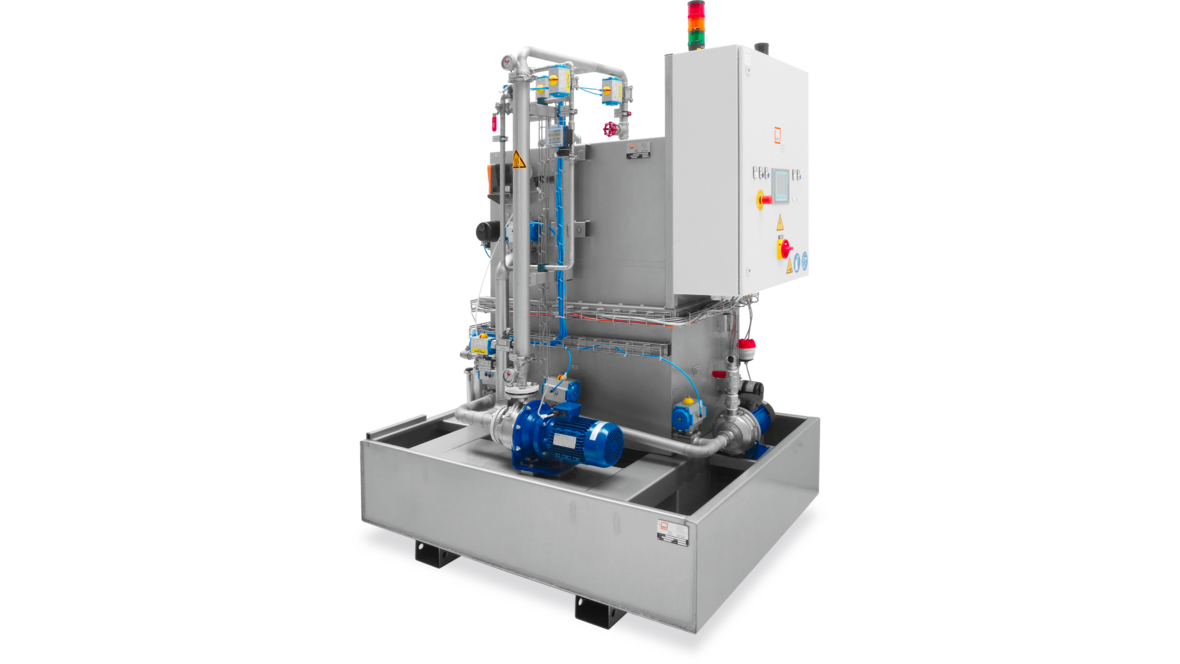

Our Evaporator systems

Maximum energy efficiency through mechanical vapor compression: Our fully automatic evaporators consume only 35 Wh/liter. Recover hygienized distillate of the highest quality for direct reuse in your production.

Our ultrafiltration systems

Our UC series uses purely mechanical ultrafiltration to separate particles, oils, and emulsions—completely without chemicals. Extend the service life of your cleaning baths many times over and ensure the consistently high quality of your process fluids.