Wastewater treatment in semiconductor and circuit board production

The manufacture of semiconductors, printed circuit boards, and electronic components is one of the most demanding industrial sectors of all. Extreme precision, purity, and process reliability are key – and this also applies to wastewater treatment. This is because etching, cleaning, electroplating, and rinsing processes produce a wide variety of chemically contaminated and sometimes toxic wastewater that must not be mixed or disposed of untreated.

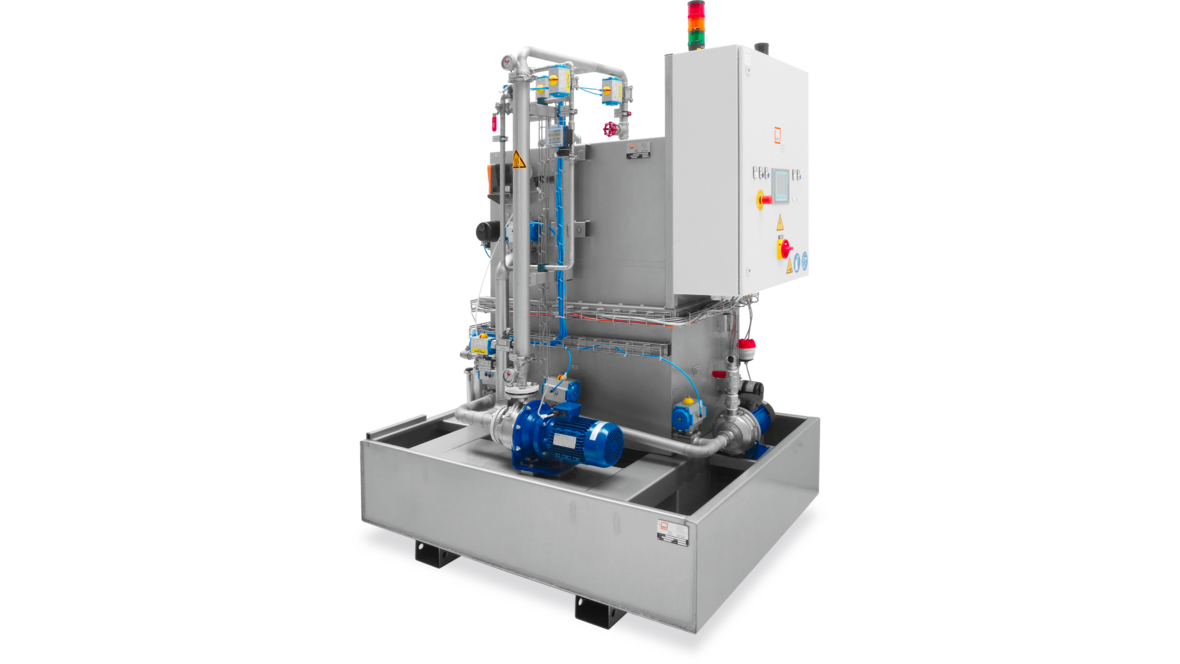

With our atmospheric evaporators, we offer a customized, economical, and ecological solution for the internal treatment of this wastewater—safe, modular, and suitable for high purity requirements.

Comply with limits. Conserve resources.

Reduce costs.

Compliance with statutory discharge limits is mandatory in the field of electronics and semiconductor production , . Even the smallest concentrations of heavy metals, acids, or alkalis can cause problems in sewage treatment plants or the environment. Our evaporator solutions enable:

- Consistent compliance with discharge limits

- Significant reduction in external disposal

- Reuse of treated water in the production process

MKR designs each system on the basis of individual wastewater analyses . This ensures that your solution is optimally tailored to your processes, volumes, and requirements.

Your advantages at a glance:

Safe treatment of heavily polluted process wastewater

Conserving resources by reusing purified water

Zero Liquid Discharge thanks to our ETMaXx technology

Modular plant technology – flexibly expandable for production expansion

Reliable, low-maintenance operation

Planning, delivery, commissioning & Service from a single source

Areas of application

Typical wastewater in semiconductor and printed circuit board manufacturing

- Rinse water from etching and electroplating processes

- Cleaning solutions containing hydrofluoric acid and hydrochloric acid

- Alkaline and acidic pickling and active baths

- Solder resist and developer rinse water

- Wastewater containing organic residues, emulsions, or heavy metals

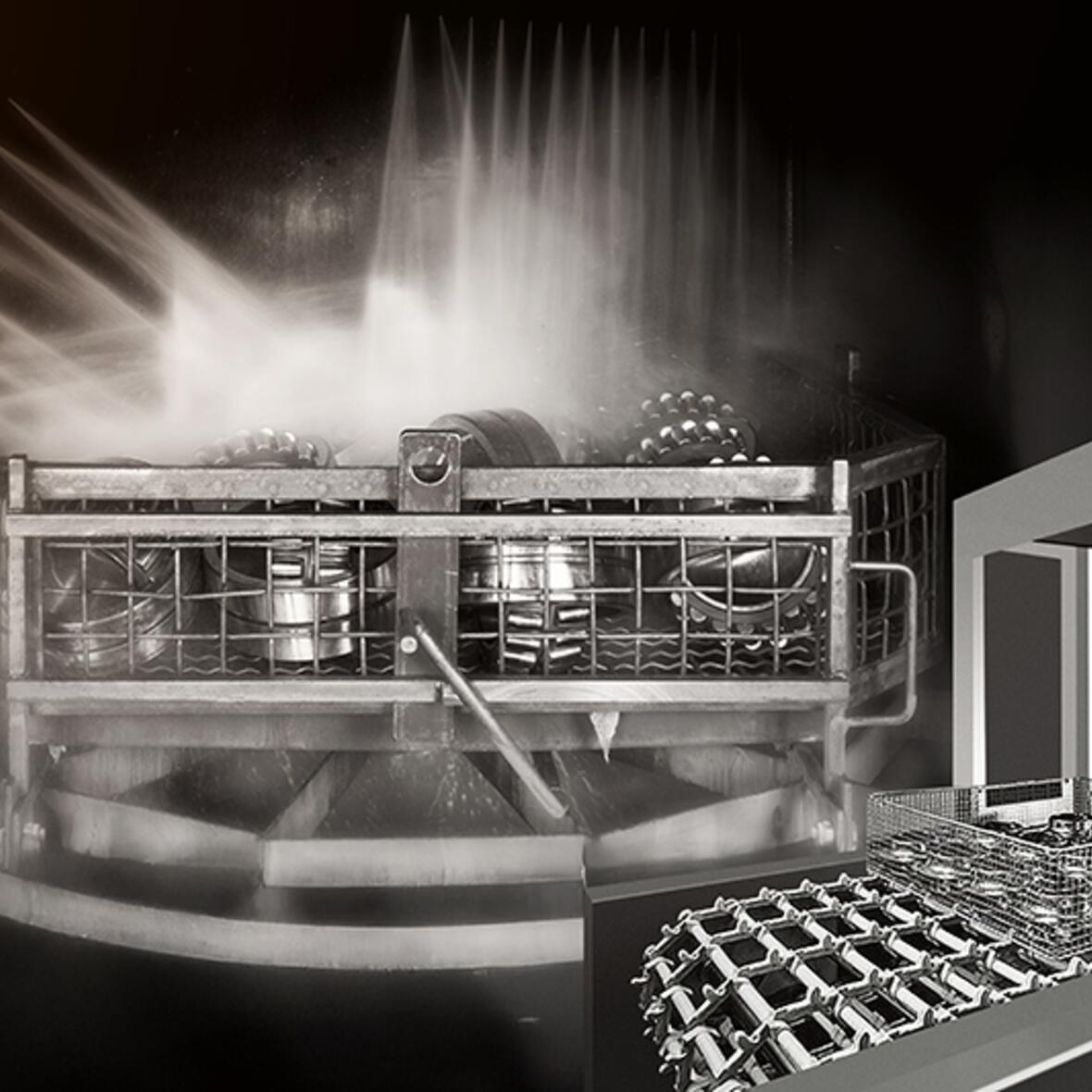

- Cleaning water from machines and production lines

Optimize processes efficiently and sustainably

Are you looking for a clean solution for your sensitive production?

With MKR's evaporator systems, you not only keep environmental requirements and quality assurance under control—you also ensure lower disposal costs and reliable process stability in the long term.

CASESTUDY - RINSING WATER FROM SEMICONDUCTOR PRODUCTION

Frequently asked questions

Our Evaporator systems

Maximum energy efficiency through mechanical vapor compression: Our fully automatic evaporators consume only 35 Wh/liter. Recover hygienized distillate of the highest quality for direct reuse in your production.

Our ultrafiltration systems

Our UC series uses purely mechanical ultrafiltration to separate particles, oils, and emulsions—completely without chemicals. Extend the service life of your cleaning baths many times over and ensure the consistently high quality of your process fluids.