Safe and sustainable treatment of wastewater from hardening plants

Reliable treatment of saline process water from quenching and cleaning processes

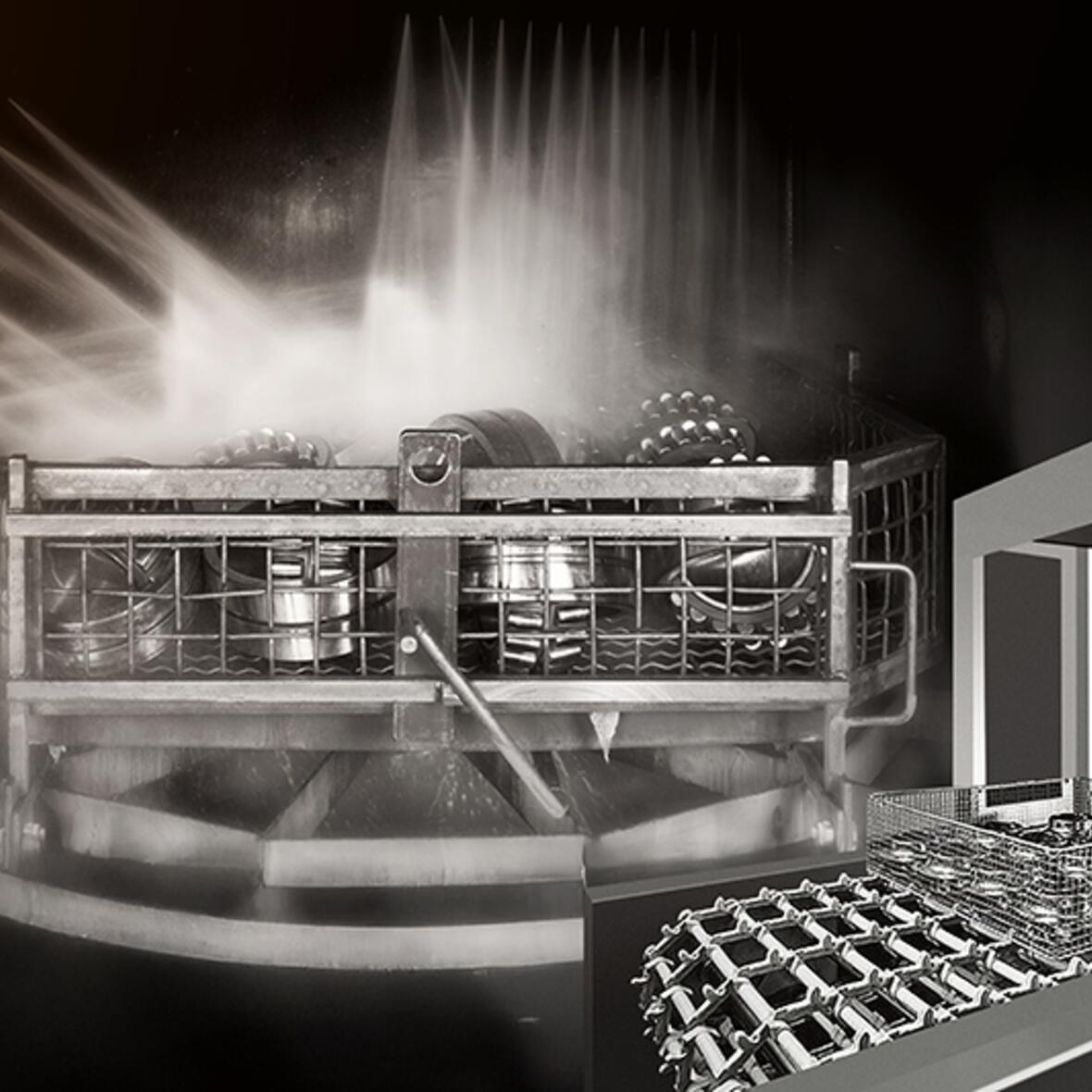

During the heat treatment of metals – especially during hardening and tempering – components are exposed to high thermal stresses. In addition to oils or aqueous solutions, saline media are also used for quenching. During the subsequent cleaning of the workpieces, highly contaminated rinse water is produced, which contains considerable amounts of hardening salt, oil, or metal particles.

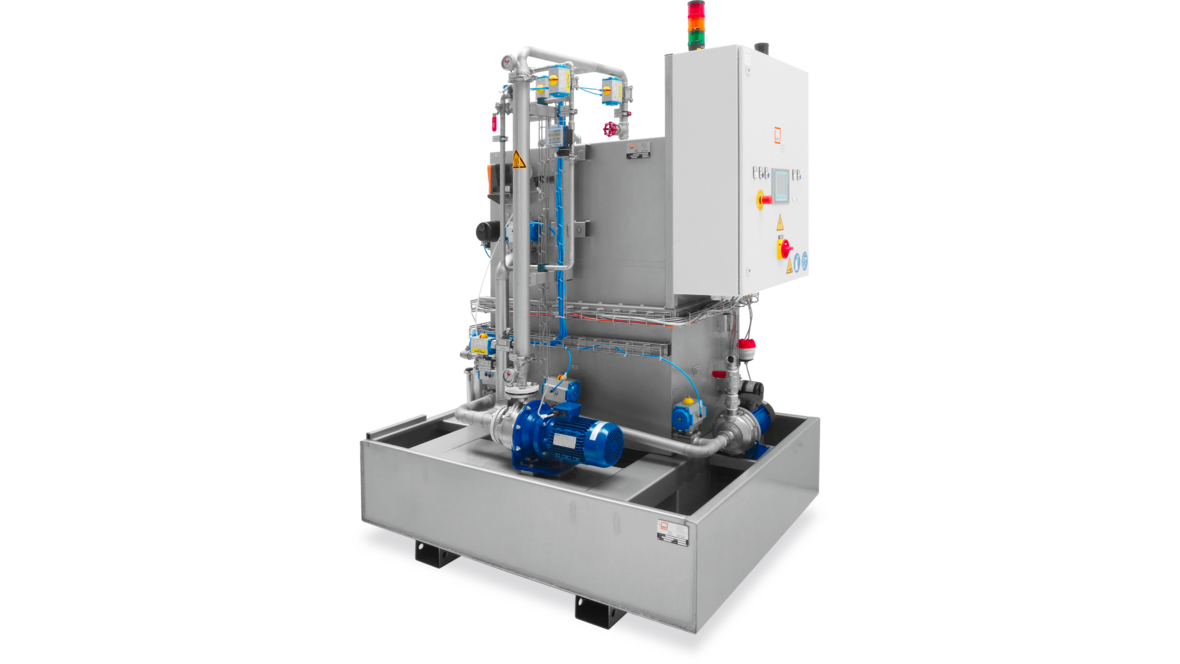

With our MKR ET evaporator series, these complex wastewater streams can be treated safely, efficiently, and in a resource-conserving manner, while even recovering valuable salts. – and even recover valuable salts.

Sustainability meets cost-effectiveness

Salts that are carried out of the bath with the workpieces often end up unused in the wastewater. This leads to rising operating costs due to the need for continuous re-dosing. With a suitable evaporator solution, these losses can be minimized and the hardening salt can be recovered for reuse – sorted by type and in a usable concentration.

At the same time, the recovered water meets the requirements for reuse or discharge , depending on process requirements.

MKR solution: Customized evaporator systems

Our experienced application team develops an individual plant concept for each customer based on:

- Analysis of the wastewater

- Process requirements

- Space and energy conditions on site

- Potential for reuse of water and salt

Our evaporator plants operate continuously and fully automatically – perfect for robust use in the hardening shop.

Your advantages at a glance

Recovery of valuable hardening salt

Reduction of wastewater volume by up to 98%

Lower disposal and operating costs

Easy introduction of purified water possible

Modular system design, individually customizable

Reliable technology – designed for continuous industrial use

Areas of application

Typical wastewater types in heat treatment

- Discharged hardening salt baths

- Saline rinsing water from cleaning

- Combined oil/salt-water mixtures from quenching processes

Optimize processes efficiently and sustainably

Do you want to make your heat treatment processes more sustainable while saving costs?

MKR offers you the expertise and technology for a future-proof wastewater solution – with a focus on resource conservation, process reliability, and cost-effectiveness .

CASESTUDY - OIL-CONTAINING WASTEWATER FROM THE HARDENING PLANT

Frequently asked questions

Our Evaporator systems

Maximum energy efficiency through mechanical vapor compression: Our fully automatic evaporators consume only 35 Wh/liter. Recover hygienized distillate of the highest quality for direct reuse in your production.

Our ultrafiltration systems

Our UC series uses purely mechanical ultrafiltration to separate particles, oils, and emulsions—completely without chemicals. Extend the service life of your cleaning baths many times over and ensure the consistently high quality of your process fluids.