CNC PRODUCTION NEEDS CONSTANT QUALITY FOR COMPETITIVE COSTS:

Mobile units for complete cleaning – the most cost-effective way to achieve longer service lives.

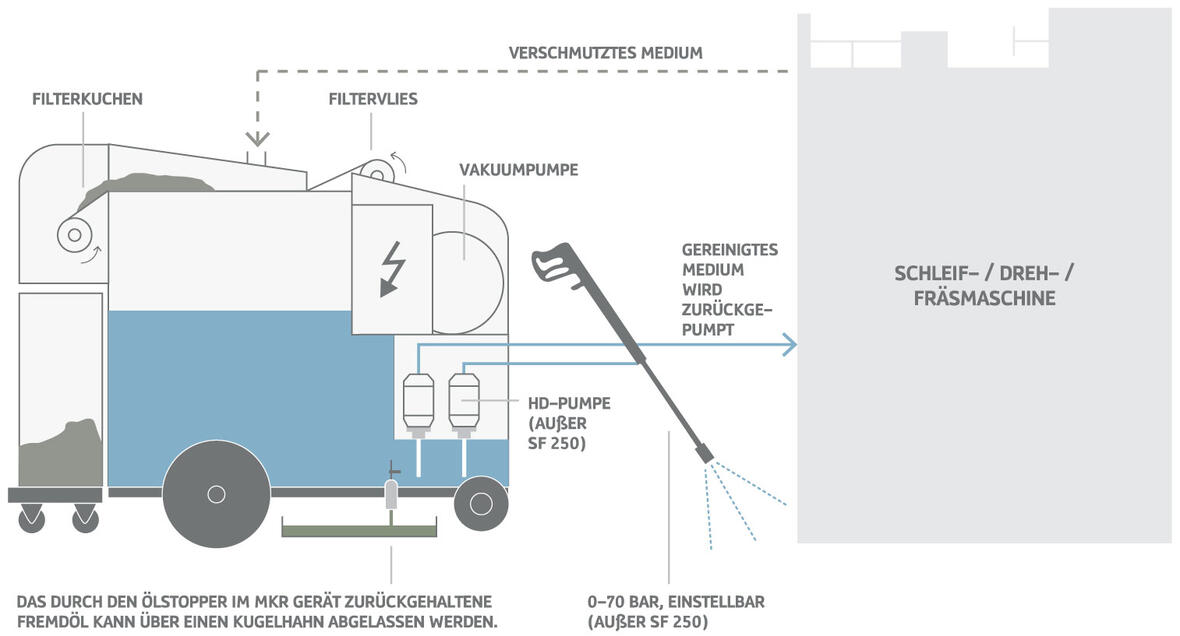

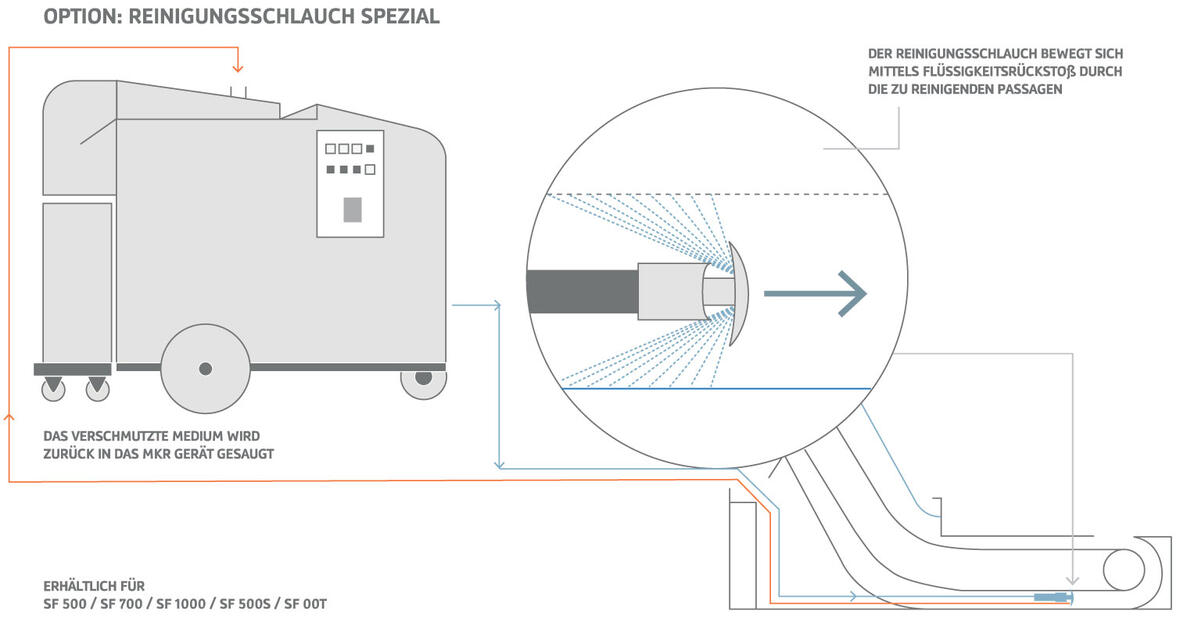

Simply go to the machining plant and clean it in next to no time: That’s how easy it is with the mobile MKR units for complete cleaning. They can be used to extract, care and then return contaminated metalworking fluid to the production process in only 15 minutes, including cleaning the metalworking fluid tank.

The high-performance MKR units type SF 500, SF 700 and SF 1000 combine several cleaning methods in one system: Liquid and swage suction apparatus, vacuum filter and high-pressure cleaner. The integrated swarf deals with solids and swage; liquids are cleaned by passing them through a vacuum filter.

The drained machine tank is cleaned using the high-pressure lance. The maintained liquid is returned to the cleaned machine by the return pump, while the tramp oils remain in the cleaning unit.

Basic image with all selectable elements.

VACCUUM AND FILTER TROLLEY AREAS OF APPLICATION:

- Metalworking fluid care

- Cutting oil cleaning

- Cleaning of the internal spaces of machines and tanks

- Complete cleaning of emulsion tanks

- Extraction of floating tramp oils

- Collection of swarf and grinding sludge

PERFORMANCE CHARACTERISTICS OF THE VACCUUM AND FILTER TROLLEYS:

- Perfect emulsion maintenance for individually filled machines

- Emulsion change in very short time

- Short machine standstill times

- Very simple handling

- Can be used for metalworking fluids or cutting-machining oils

MKR SF product series: The comprehensive solution with 4 functions in one machine

Extraction:

Swarf and grinding swarf are extracted reliably from soiled metalworking fluids using the suction spout. The high suction and pumping capacity of the MKR unit minimises the time required to clean machines and emulsions.

Filtering:

Thanks to vacuum filters, chips (swarf) and grinding sediments up to 80 µm in size are separated from the emulsion reliably.

High-pressure lance:

It can even flush out stubborn deposits and oil dirt -

cleanliness through to the smallest corner of the machine interior.

Swarf:

It absorbs the metal particles filtered out of the medium; it can also be used as an independent vacuum cleaner.