PROCESS

Whether in the mobile version or used as a stationary system: Disc stack centrifuges by MKR clean metalworking fluids, cutting oils and washing media in bypass mode during on-going operations.

The respective process medium is pumped from the machine tank and is then pumped through a centrifuge. The cleaned liquid, from which particles and tramp oils have been removed, is then returned to the production plant or washing system. This means that the media can be used longer – without quality loss, as confirmed by the leading manufacturers of process media. This means lower consumption and disposal costs.

Another positive aspect is the ability to select the separator type for a specific interfering factor. Depending on the MKR machine type, separators with sludge removal, de-oiling or combined action are used. They enable cleaning capacities from 300 to 3000 litre per hour. In addition to tramp oils, ultrafine particles up to a size of 2 µm are removed. And what is also practical: The separators operate uniquely with the physical principles of

centrifugal force and gravity. They therefore require no filter aids whatsoever.

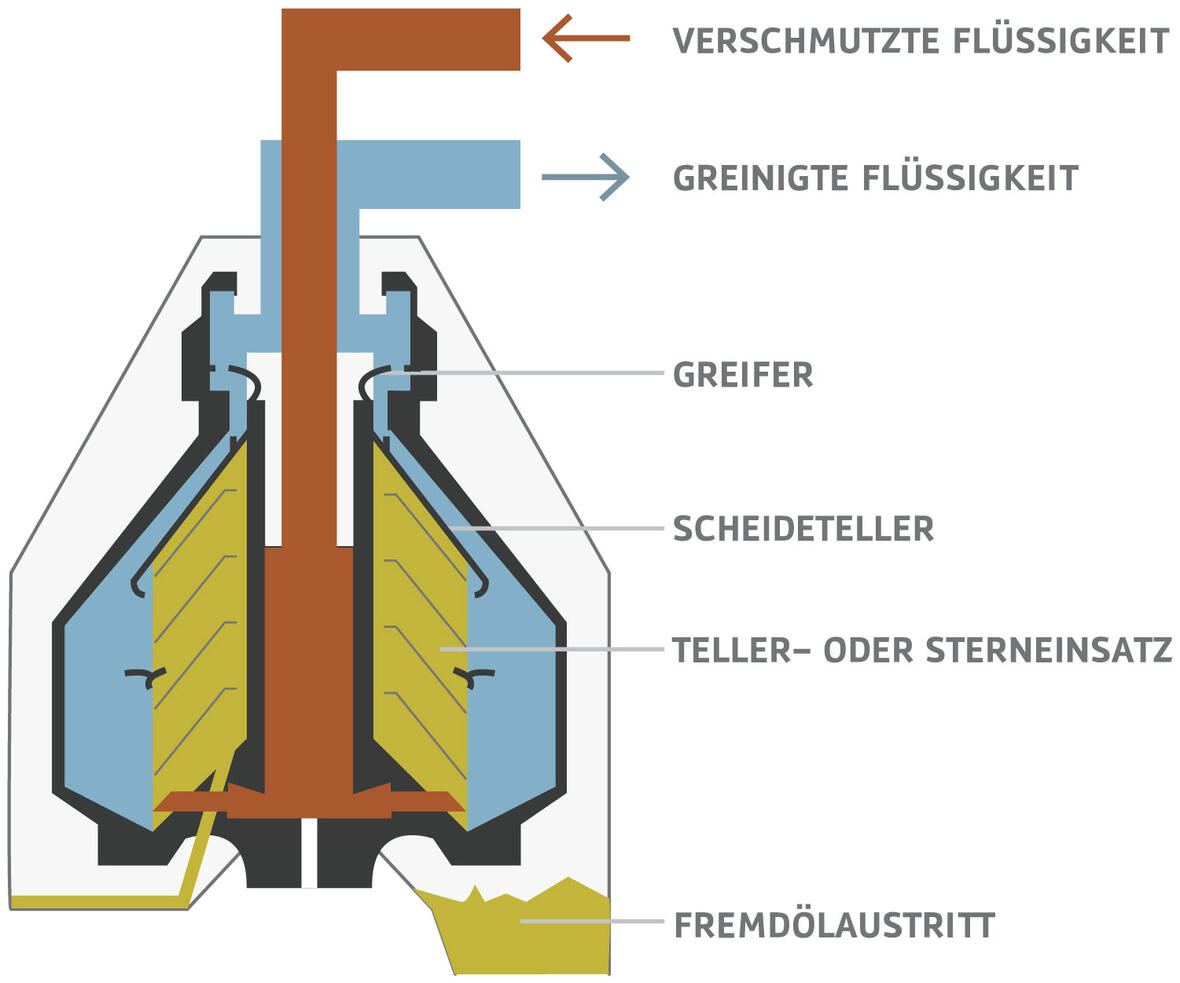

THREE-PHASE DISC-STACK SEPARATOR

It ensures complete and exact tramp oil and solid removal. In addition, water can be removed from hydraulic fluid cycles. MKR offers the choice between separators that collect solids and self-sludge removal separators. Tramp oil is absorbed and separated – regardless of whether the oil is floating on the surface or is dispersed in the metalworking fluid due to turbulence.